NO PROBLEMS JUST SOLUTIONS!

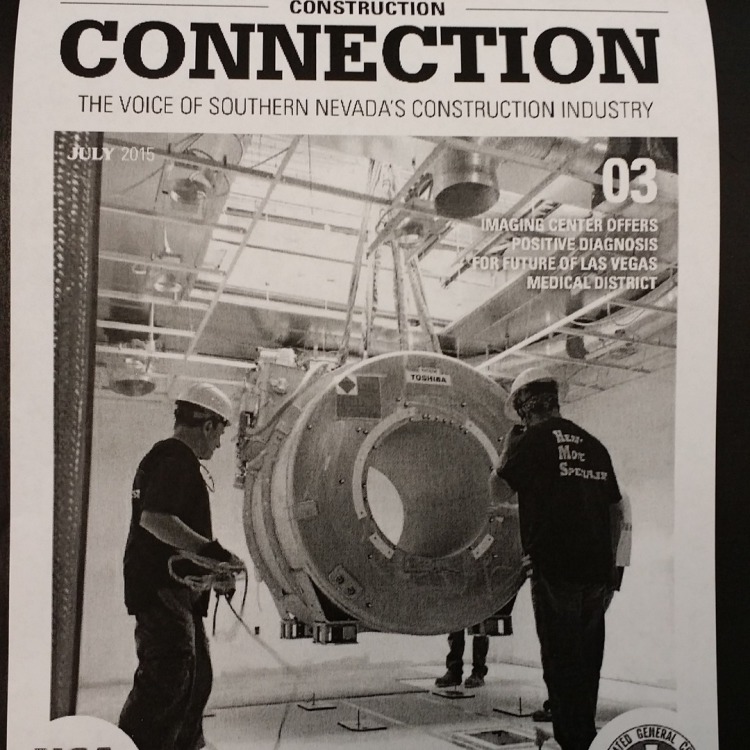

We are an experienced rigging company that primarily works in and around Las Vegas. We move heavy machinery such as MRI'S, CT UNIT, X-RAY UNITS, C-ARM'S, CHILLERS, FLIGHT SIMULATORS, TRANFORMERS, GENERATORS, SWITCH

GEAR, PUNCH PRESS, SHEARS, BRAKE PRESS, MILLING MACHINES, LATHES, INDUSTRIAL LAUNDRY MACHINES, PUMPS AND CNC MACHINES, MODULE BUILDNGS ETC.....

USING HYDRAULIC JACKS AND SKATE, CRANES, FORKLIFTS ALONG WITH OUR SPECIALIZED RIGGING AND CRIBBING METHODS. WE MOVE HEAVY

EQUIPMENT AND MACHINERY IN AND OUT OF ANY TIGHT SPACE OF PLACE.

STORAGE

HMS also offers storage facilities to meet all your short or longterm needs. We have everthing from mini storage units to large, climate

controlled spaces. for more information contact us at 702-750-7275

The Need for Heavy Machinery Moving

In various industries, heavy machinery and equipment are the backbone of productivity and profitability. These machines are used

for tasks ranging from excavation and material handling to manufacturing and construction. However, these machines are not stationary; they need to be relocated for various reasons:

1. **Site Changes:** Construction projects often involve moving heavy machinery from one job site to another as the project

progresses.

2. **Maintenance:** Machinery may require relocation for routine maintenance or repairs, especially if the equipment is too large

or complex to be serviced on-site.

3. **Upgrades:** As technology advances, companies may invest in newer, more efficient machinery, requiring the removal and

replacement of older equipment.

4. **Facility Relocation:** When a company relocates its operations to a new facility, it must transport its heavy machinery to

the new site.

The Challenges of Heavy Machinery Moving:

Moving heavy machinery presents numerous challenges, which is why it requires specialized expertise and equipment:

1. **Size and Weight:** Heavy machinery can range from several tons to hundreds of tons in weight, and it may have dimensions

that exceed standard transportation limits.

2. **Complexity:** These machines often consist of intricate components and systems that must be disassembled and reassembled

correctly.

3. **Safety:** The safety of personnel, the machinery itself, and the environment is a paramount concern during heavy machinery

moving.

4. **Transportation:** Transporting heavy machinery requires specialized vehicles and equipment, including heavy-duty trailers,

cranes, and rigging.

The Heavy Machinery Moving Process:

The process of moving heavy machinery typically follows a structured series of steps:

1. **Assessment:** Before any move, an assessment of the machinery and the route is conducted. This includes evaluating the

machinery's weight, dimensions, and any special handling requirements.

2. **Planning:** Detailed planning is essential, including obtaining permits, coordinating with local authorities for road

closures (if necessary), and developing a schedule.

3. **Preparation:** The machinery is prepared for transport, which may involve disassembling components, securing loose parts,

and ensuring the equipment is in optimal condition for the move.

4. **Transportation:** Specialized transport vehicles, such as flatbed trucks or lowboy trailers, are used to transport the

machinery to its destination. In some cases, oversized loads require pilot vehicles and police escorts for safe passage.

5. **Lifting and Rigging:** Cranes and rigging equipment are used to lift and load the machinery onto the transport vehicle, as

well as to unload and position it at the destination.

6. **Assembly and Installation:** Upon arrival at the new location, the machinery is reassembled, calibrated, and installed to

ensure it operates correctly.

7. **Testing and Inspection:** Comprehensive testing and inspection procedures are carried out to verify that the machinery is

functioning as expected.

8. **Safety Protocols:** Throughout the process, safety protocols are strictly adhered to, including securing the machinery to

prevent accidents during transport.

The Importance of Expertise:

Due to the complexities and potential risks involved in heavy machinery moving, it's crucial to engage professionals with the

expertise and experience required to carry out these tasks safely and efficiently. Specialized heavy machinery moving companies employ skilled technicians, engineers, and riggers who are well-versed

in the intricacies of moving heavy equipment.

Safety is a primary concern throughout the process. Professionals are trained to mitigate risks associated with heavy machinery

moves, including potential damage to the equipment, harm to personnel, and impact on the environment. They use advanced rigging techniques, safety protocols, and cutting-edge equipment to ensure a

smooth and secure move.

In addition to the technical aspects, regulatory compliance is a key consideration. Heavy machinery moving often involves

obtaining permits and adhering to local, state, and federal regulations governing the transportation of oversized loads. We have a thorough understanding of these regulations and can navigate the

permitting process efficiently.

Heavy machinery moving is a critical component of many industries, allowing companies to relocate, upgrade, and maintain their

vital equipment. However, it is a complex and highly specialized process that requires meticulous planning, expertise, and a strong focus on safety. Companies that rely on heavy machinery moving

services can benefit from reduced downtime, minimized risks, and the assurance that their valuable equipment will be transported and installed with the utmost care and precision.